Citation:

Abstract:

This case focuses on the establishment of the Olyset® Consortium—a public-private partnership that was created to facilitate the manufacture of long-lasting insecticidal bed nets to prevent malaria infection in sub-Saharan Africa—and A to Z Textile Mills (“A to Z”), the manufacturer of the nets in Arusha, Tanzania. The case examines how the public-private partnership was developed, its use of an incentive-based supply chain, A to Z’s business model and impact, and the sustainability of the venture. The case reveals that despite significant success in attaining objectives, the misaligned incentives of the many partners presented major obstacles to the overall sustainability of A to Z’s Olyset® production line.

Teaching Note available through Harvard Business Publishing.

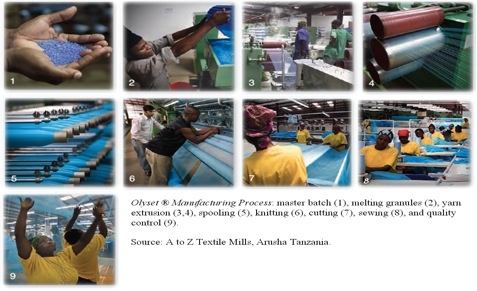

Long Lasting Insecticide Nets and Olyset Production Process. Source: A to Z Textile Mills Ltd., Arusha, Tanzania (Case Exhibit 9).

Learning Objectives: To understand the potential for public-private partnerships to leverage innovation and scalability from the private sector and quality and equitable access from the public sector and to examine the costs and benefits of local manufacturing of technologically complex global health commodities in resource-limited settings.

Keywords: Public-private partnerships, incentive-based supply chain, global health commodity manufacturing, malaria prevention